How To Build A DIY Resistance Soldering Unit

What’s In This Page

This is a directory page with information related to building a resistance soldering iron (RSI) for fine scale brass modeling. Because our instructions are illustrated and detailed. it is best to download our free instruction guide that you can use without having to stay connected to the internet. It is described and linked below.

There are also images of some models made with an RSI.

Finally there is a large collection of tutorials on resistance soldering.

If you are using a phone, at the bottom of the page there are links to many supplies for modelers. Otherwise those links are in the sidebar to the right. You can also find other information by using the search function that is in the navigation bar above.

The Latest Information

Anything new and page updates are posted on Twitter (now X) and Facebook.

It is easy to keep up with the latest by following us on either of them.

A tutorial for making circuit using a circuit board that will provide versatility as well as save you time and labor.

Start by downloading this free, 31 page, illustrated guide. To get your copy, either click on the image or on this link.

It is fully illustrated and quite detailed. Reviews by those who have used it are excellent.

Features

- Safe transformer with European Union Safety Certificates.

- Made for fine scale modeling including etched brass kits.

- Voltage Outputs 3 volts amps, 6 amps.

- Solder etched brass kits without warpage.

- Join track and add power leads without melting sleepers

- Solder light steel.

- Uses either 115 v-AC or 230-v AC input power.

- Use workshop wall power plug designed for your country.

- Multi-functional probe capability.

- Simple assembly

- Affordable, low cost complete kit.

- Illustrated 31 page assembly guide.

Uses

You will find that you will need both a conventional soldering iron and a resistance soldering iron on your bench. The conventional iron is necessary for such tasks as soldering elements on circuit boards and attaching magnet wire to SMD LEDs. But for most everything else, you will find it better to use a resistance soldering iron.

Specifically, you will use it for things like this.

- Soldering etched brass kits safely without warping the pieces or having excess solder on pieces that must be cleaned up.

- Connecting track and adding power leads without melting sleepers.

- Scratch building brass models of all kinds.

Instructions

This shows the completed unit described in this page. Download a free, 31 page, fully illustrated guide that shows you step by step how to build one for yourself. To get your copy click here.

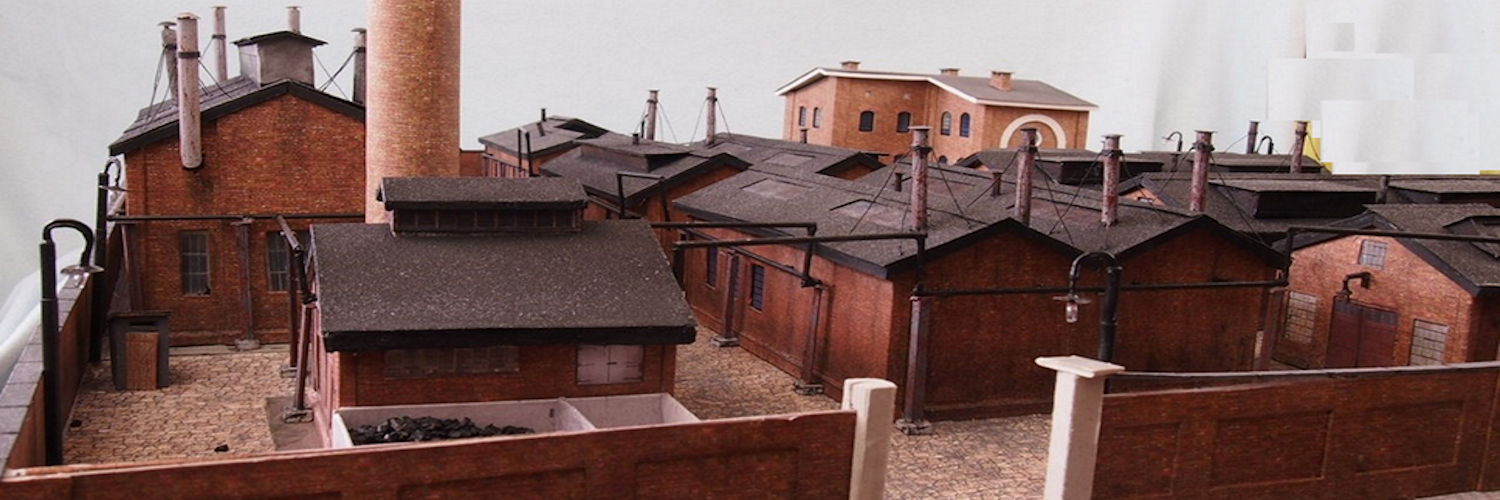

Examples

Here are four examples of projects made using a resistance soldering iron. You can watch videos showing the construction process at this link.

Resistance Soldering Video Tutorials

This link takes you to a full playlist of videos related to resistance soldering. Click here.

Resources

About DIY Resistance Soldering Irons –

Why Resistance Soldering Instead Of Conductive Soldering –

How To Make And Use Resistance Soldering Pickle –

Resistance Soldering Frequently Asked Questions –

How To Make Resistance Soldering Iron Tools –

Resistance Soldering Tips And Hints –

Feedback

Your questions and comments help us clarify and upgrade the information presented. Even if you find this helpful, please tell us.

Please let us know if this page has been helpful And if you have questions or suggestions, use this spam free system.

Or use the green WhatsApp button that is to the right.