How To Install An IR Sensor

Under HO And OO Scale Track

Page update in progress

How To Prepare And Install IR sensors under your track.

What’s In This Page

This pages presents a solution to problems that occur when you install IR sensors under track.

If you are using a phone, at the bottom of the page there are links to many supplies for modelers. Otherwise those links are in the sidebar to the right. You can also find other information by using the search function that is in the navigation bar above.

All page and site updates are posted in our Twitter Channel. You can check by clicking here.

And our FaceBook page is here.

The problems that you face are:

The 5 mm emitters and sensor LEDs that come with the IR sensors as you buy them do not fit between the rails.

To install a sensor under the track it requires a that you cut a large hole and even then it is difficult to adjust for a proper fit.

When the sensor is under the track, it is difficult to adjust the sensitivity.

The solution starts with removing the 5 mm LEDs from the sensor body and replacing them with 3mm leds soldered to a measured length of telephone wire.

The result is:

you install only the emitter and sensor LEDs under the track. They fit in small holes between the rails,

you install only the emitter and sensor LEDs under the track. They fit in small holes between the rails,

the emitters and sensors are connected by long wires to the sensor body that is mounted at a convenient remote place,

because the sensor body is conveniently located, sensitivity can be adjusted without working under the track.

Procedure

Solder the 3 mm replacements to telephone wire. Be sure to add shrink tube. I cover each of the legs and then cover those with a larger diameter piece. Extend the larger diameter piece beyond the end of the LED.Be sure to somehow identify the cathode wire for each.

Use something to hold the sensor body firmly, melt the soldered pins and pull the 5mm detectors out.

Use a solder sucker to empty the holes of any remaining solder.

In the holes left in the sensor body after removing the 5 mm versions, solder female mechanical pin headers.

This shows the pin headers soldered in place and LEDs inserted into the headers. This is for illustration only.

The LEDs will be at a remote location from the sensor body.

You will mount the sensor body on a control board of some sort.

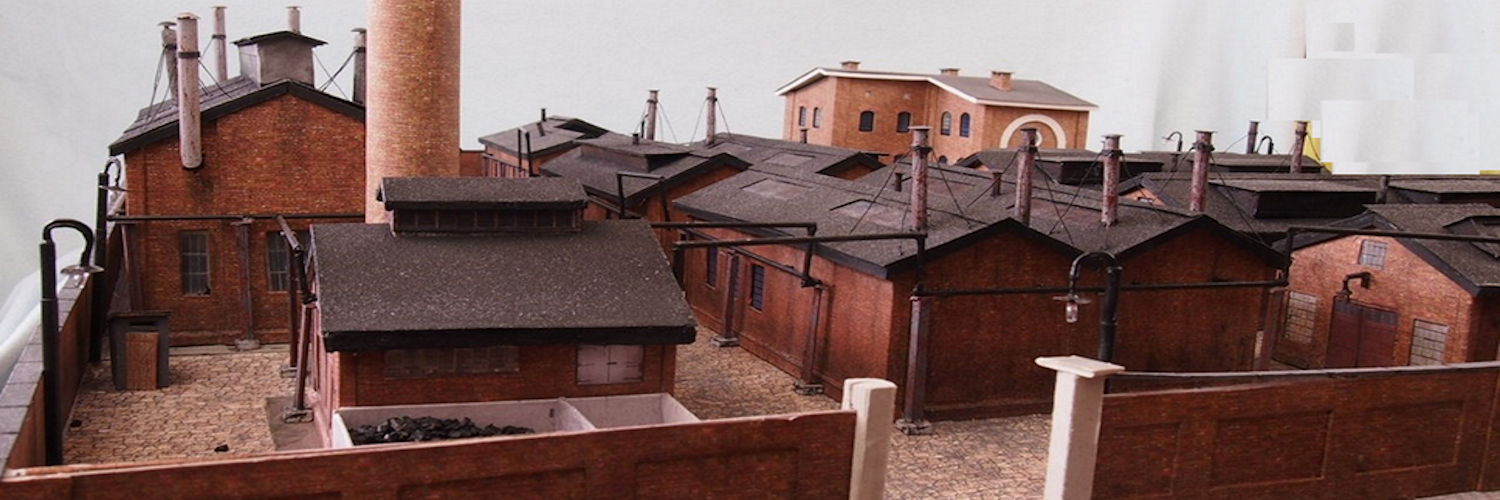

This control board will be used on a 3 track level crossing. There is a complete video series on making level crossing in the video gallery above.

Cut the telephone wires to the length between detector placement and the control board. (Leave a bit extra to CYA).

Cut the telephone wires to the length between detector placement and the control board. (Leave a bit extra to CYA).

Put one end of the wires in a drill, hold the emitters and twist the wire. You now have a spagehtiless wire run.

Normally the cathode wire goes on the center most pin joints.

Adjust wire length as necessary.

Solder the wire ends to female mechanical pin headers. Plug them into the sensor body.

Fit each sensor and emitter inside black shrink tube. Extend the tube beyond the sensor face. This will better hide and focus them. Adjust sensor sensitivity as necessary.

With the sensor body on a control board and the detectors at a distance and under the track, you can easily adjust sensitivity without having to go under the track.

Roll a wagon over the detectors and conveniently adjust sensitivity.

Feedback

Your questions and comments help us clarify and upgrade the information presented. Even if you find this helpful, please tell us.

Please let us know if this page has been helpful And if you have questions or suggestions, use this spam free system.

Or use the green WhatsApp button that is to the right.